ULTRASONIC WELDER ( HAND GUN TYPE or PORTABLE TYPE)

used in making detailed and various designs of bases

using Nylon Monofilament Nets ( non-processed or

head-shaped by CW451-TBL) and Nylon Thread

1. Please switch on ( #1) to make an electrical connection. ( Voltage: 220V)

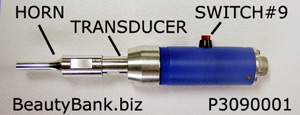

2. Without connection of Transducer equipped with a horn (P3090001), please push the Switch to see if the control box works well.

If the needle of Current Meter (#6, or P3110020) moves between 0.1 ~ 0.2, which means the control box is working properly.

3. Please have the transducer (with a horn ) connected to the control box using the connector ( P3090005).

And, please push the Switch #9 (or, #2) in order to see (1) if the transducer works well, (2) if the Transducer and a Horn is connected well, (3) if the horn is not broken.

If the needle moves between 0.2 ~ 0.4, the whole system works normally.

Meanwhile if the needle

goes over 0.4, please do tuning with the switch (#4) to minimize the current

amount coming

As tuning, please stop it when you see the needle go to the minimum no

(amount).

When you change Horns, please be sure to check the amount of current and

fix the same way.

When you do checking or

testing, please use Switch #9 of Transducer or, Switch #2 in the control

box).

Then, please do not push the switch for a long time. Which can demage

the system or the welder, mainly the horn).

Just push the red switch (#9) for a 0.3 second, or shortly,

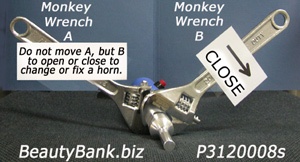

RE: Changing Horns

For general works, we use Horn C

( Circle Shape). Sometimes, we need to use Horn L ( Line drawing), or

S ( Spot making ).

Then, please do not fix ( or tighten ) too tightly ( by force). Otherwise,

there can be too much amount of current generated and the horn or the

system can be broken or demaged.

Most of problems have something to do with Horns.

Power supply must be done regularly.

Eletrical impact or physical shock must not be given to horns.

Every time, be sure to have a test to see if there is proper amount of current generating.

Please keep a Horn from touching any metal piece directly. The horn can be broken because too much current will be generated.

It is all right to touch nylon net on a metal mold.

We put a fan to the control box in order to cool down the system, which cause a little noise. It is normal.

Foot Switch can be used just Switch #2, #9 or, #3. But, most of workers do not use the Foot Switch.